ASME B16.11 Thredolet Fitting Manufacturers and Suppliers:

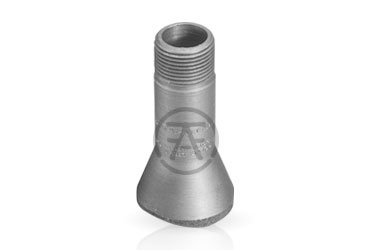

A Thredolet is a type of branch connection fitting used in piping systems to create a threaded outlet from a larger pipe. Thredolets are typically used in low-pressure applications and can be made from various materials such as carbon steel, stainless steel, and alloy steel.

ADCO Forge and Fittings is a manufacturer of Thredolets and other pipe fittings. We offer a variety of materials and sizes to meet the needs of various piping systems.

ISO Approved ASME/ANSI B16.11 Thredolet Manufacturer In India, ASME B31.3 Thredolet Fittings, MSS SP-97 Thredolet Dimensions Chart, Tolerances, Weight Chart, Thickness Chart, Cad Drawing

The dimensions of a Thredolet can vary depending on the size of the pipe it is being used on, but it generally has a small branch connection that is threaded to connect to the outlet pipe. Thredolets are governed by industry standards such as MSS SP-97, which outlines the design and testing requirements for branch connection fittings.

Thredolets can also come in reducing sizes, allowing for a smaller branch connection to be created from a larger pipe. BSP, NPT, and BSPP are common thread types used on Thredolets, with BSP and NPT being more common in the United States and BSPP being more common in Europe.

Thredolets are rated based on their pressure and temperature capabilities, with common classes including Class 150 and Class 3000. These ratings indicate the maximum pressure that the fitting can withstand at a given temperature.

We have the ready inventory of Thredolet Fitting in the different size ranges of 4 Inch, 1/2 NPT, 0-80 thread size, 1 Inch, 1 1/2 EMT, 2 Inch, 3 Inch, 3/8 NPT, 4 Inch, 5 Inch, 5/32 NPT, 6 Inch, 7 Inch Thredolets.

Thredolet Fitting Standard Specifications

Standards

ASME B31.3, B31.1, B31.8, B31.4, ASME/ANSI B16.11, MSS-SP-97

Thickness

SCH 5S, SCH 10S, SCH 40S, SCH 80S, SCH 120S

End

Female Threaded, Male Threaded

Dimensions

ASME B31.3,1,8,4 | ASME/ANSI B16.11 | MSS-SP-97 | JIS B2316 | BS 3799

Size Range (inches)

From 2″ – 24″

Class

6000LBS, 3000LBS

Schedule 40 & Schedule 80 Thredolet in Stainless Steel 304/304L, SS 316/316L, SS 904L, Alloy 20, Carbon A234 WPB, Nickel 200, Monel, Inconel, Hastelloy C22, Duplex Steel 2205, Titanium, Copper Nickel, SMO 254, Aluminum, Brass, Cast Iron, Galvanized, MS Thredolet. Get best Price List.

ASME B16.11 Outlet Fittings Types

If you are looking for ASME B16.11 Olets Fittings types, weight chart, size chart, tolerance, and dimensions with drawings then kindly click the below-mentioned forms of pipe fittings as per your requirements to get the complete details. For the quick quote / price list click here.

ASME B16.11 Thredolet Material Grades

| Stainless Steel Thredolet: | ASTM A182/SA182 WP Gr. 304, 304L, 304H, 310, 310S, 316, 316L, 316H, 316Ti, 317, 317L, 321, 321H, 347, 347H, 446, 904L |

|---|---|

| Carbon Steel Thredolet: | ASTM A105/SA105, ASTM A694/SA694, Gr. F42/46/52/56/60/65/70 |

| Low Temperature Carbon Steel Thredolet | ASTM A350 LF3/A350 LF2 |

| Alloy Steel Thredolet: | ASTM A182/SA182 F1/F5/F9/F11/F22/F91 |

| Duplex & Super Duplex Thredolet: | ASTM A182, ASME SA182 F 44, F 45, F51, F 53, F 55, F 60, F 61. |

| Nickel Alloy Thredolet: | ASTM / ASME SB 564 / 160 / 472 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UND 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C276 ), Cupro Nickel 90/10 ( C70600, 2.0872 ), 70/30 ( C71500, 2.0882) |

| Other Steel Thredolet: | ASTM B363 Titanium Grade 2 ( R50400, 3.7035 ), Titanium Grade 2 ( N56400, 3.7165 ), ASTM A403 SMO 254/AL-6XN ( S31254, 1.4547 ), AISI 4130 ( G41300, 1.7218 ) |

ASME B16.11 Thredolet Dimensions

ASME B16.11 Thredolet - Dimensions Chart

Dimensions of Thredolet (Class 3000)

| Size in Inches | A | B | C | Weight in KG |

|---|---|---|---|---|

| 1/8 | 19.05 | 25.40 | 15.88 | 0.05 |

| 1/4 | 19.05 | 25.40 | 15.88 | 0.05 |

| 3/8 | 20.64 | 31.75 | 19.05 | 0.09 |

| 1/2 | 25.40 | 35.72 | 23.81 | 0.11 |

| 3/4 | 26.99 | 43.66 | 29.37 | 0.16 |

| 1 | 33.34 | 50.80 | 36.51 | 0.27 |

| 1 1/4 | 33.34 | 65.09 | 44.45 | 0.41 |

| 1 1/2 | 34.93 | 72.23 | 50.80 | 0.45 |

| 2 | 38.10 | 88.11 | 65.09 | 0.79 |

| 2 1/2 | 46.04 | 103.19 | 76.20 | 1.36 |

| 3 | 50.80 | 122.24 | 93.66 | 1.97 |

| 3 1/2 | 53.98 | 132.56 | 101.60 | 2.61 |

| 4 | 57.15 | 151.61 | 120.65 | 3.22 |

| 5 | 66.68 | 185.74 | 141.29 | 5.44 |

| 6 | 69.85 | 219.08 | 169.86 | 6.94 |

Dimensions of Thredolet (Class 6000)

| Size in Inches | A | B | C | D | Weight in KG |

|---|---|---|---|---|---|

| 1/4 | 28.58 | 34.13 | 14.29 | 0.14 | |

| 3/8 | 28.58 | 34.13 | 14.29 | 0.14 | |

| 1/2 | 31.75 | 43.66 | 19.05 | 0.20 | |

| 3/4 | 36.51 | 49.61 | 25.40 | 0.34 | |

| 1 | 39.69 | 61.91 | 33.34 | 0.57 | |

| 1 1/4 | 41.28 | 69.06 | 38.10 | 0.73 | |

| 1 1/2 | 42.86 | 82.55 | 49.21 | 0.88 | |

| 2 | 55.03 | 102.39 | 69.85 | 2.27 |

Dimensions of Thredolet (Size on Size Class 3000 Dimensions)

| Size in Inches | A | B | C | D | Weight in KG |

|---|---|---|---|---|---|

| 1/2 | 25.40 | 34.93 | 23.81 | 15.88 | 0.07 |

| 3/4 | 26.99 | 41.28 | 30.16 | 20.64 | 0.11 |

| 1 | 33.34 | 50.80 | 36.51 | 26.99 | 0.20 |

| 1 1/4 | 33.34 | 60.33 | 44.45 | 34.93 | 0.32 |

| 1 1/2 | 34.93 | 73.03 | 50.80 | 41.28 | 0.41 |

| 2 | 38.10 | 88.90 | 65.09 | 52.39 | 0.64 |

| 2 1/2 | 48.42 | 103.19 | 76.20 | 63.50 | 1.13 |

| 3 | 50.80 | 122.24 | 93.66 | 77.79 | 1.95 |

| 3 1/2 | 53.98 | 136.53 | 112.71 | 90.49 | 2.04 |

| 4 | 57.15 | 153.99 | 120.65 | 103.19 | 3.08 |

| 5 | 61.91 | 184.15 | 133.35 | 133.35 | 4.17 |

| 6 | 69.85 | 220.66 | 146.05 | 146.05 | 7.12 |

Q: What is a Threadolet?

A: A Threadolet is a type of branch connection fitting used in piping systems. It is designed to provide a convenient and reliable way to create a smaller branch connection on a larger pipe or vessel. The Threadolet has a female threaded outlet, which allows for the installation of a threaded pipe or fitting.

Q: What is the difference between a Weldolet and a Threadolet?

A: While both Weldolets and Threadolets are branch connection fittings, there are a few key differences between the two:

- Connection Type: The primary difference lies in the method of connection. A Weldolet is welded directly onto the main pipe or vessel, whereas a Threadolet is threaded into the pipe or vessel.

- Installation Process: Weldolets require welding, which involves heating the connection area and fusing the Weldolet to the pipe or vessel. Threadolets, on the other hand, can be installed without welding and are simply threaded into the existing pipe or vessel, making them relatively easier to install.

- Pressure and Temperature Ratings: Weldolets generally have higher pressure and temperature ratings compared to Threadolets. This is because the welding process provides a stronger and more secure connection, making Weldolets suitable for high-pressure and high-temperature applications. Threadolets, while still capable of handling significant pressures and temperatures, may have slightly lower ratings.

- Versatility: Weldolets are commonly used for butt-weld connections, whereas Threadolets are primarily used for threaded connections. Weldolets are available in a wider range of sizes and materials, providing more versatility in terms of pipe size and material compatibility.

- Flexibility: Threadolets offer more flexibility in terms of installation and maintenance. They can be easily removed and replaced, allowing for modifications or repairs without extensive welding work. Weldolets, once welded, are generally more permanent and require more effort to modify or replace.

MSS SP-97 Thredolet Applications

Oil and Gas

Nuclear Power & Defence

Petrochemical

LNG

Desalination

Mining & Minerals

Myanmar, Nepal, Thailand, Vietnam, Philippines, Malaysia, Indonesia,

Singapore, Taiwan, Tasmania, Sri Lanka, Bangladesh, Bhutan, Cambodia,

Australia, New Zealand, Afghanistan, Tajikistan, Kyrgyzstan, Kazakhstan,

Uzbekistan, Turkmenistan, Iran, United Arab Emirates(UAE), Saudi Arabia,

Oman, Yemen, Iraq, Azerbaijan, Turkiye, Syria, Lebanon, Israel, Kenya,

Egypt, South Sudan, Eritrea, Djibouti, Ethiopia, Libya, Rwanda, Mali,

Niger, Chad, Central Africa Republic, Nigeria, Cameroon, Somalia, DRC,

Uganda, Tanzania, Angola, Zambia, Madagascar, Malawi, Namibia, Benin,

Zimbabwe, Botswana, Lesotho, South Africa, Algeria, Tunisia, Morocco,

Eswatini, Liberia, Sierra Leone, The Gambia, Senegal, Mozambique, Togo,

Mauritania, Burkina Faso, Ghana, Equatorial Guinea, Jordan, Timor-Leste,

Palestine, Laos, Armenia, Georgia, Maldives, Cyprus, Kuwait, Qatar, Peru,

Bahrain, Brunei, Finland, France, Germany, Ireland, Iceland, UK, US,

Greece, Hungary, Italy, Norway, Poland, Slovakia, Sweden, Canada, Fiji,

Romania, Cuba, Panama, Brazil, Colombia, Chile, Argentina, Venezuela,

Naypyidaw, Kathmandu, Bangkok, Hanoi, Manila, Kuala Lumpur, Jakarta, Tunis,

Jurong East, Taipei City, Hobart, Sri Jayawardenepura Kotte, Dhaka, Thimphu,

Phnom Penh, Canberra, Wellington, Kabul, Dushanbe, Bishkek, Astana, Abuja,

Tashkent, Ashgabat, Tehran, Abu Dhabi, Riyadh, Muscat, Sana’a, Baghdad, Pretoria,

Baku, Ankara, Damascus, Beirut, Jerusalem, Nairobi, Cairo, Juba, Asmara, Rabat,

Djibouti city, Addis Ababa, Tripoli, Kigali, Bamako, Niamey, N’Djamena, Bangui,

Yaoundé, Mogadishu, Kinshasa, Kampala, Dodoma, Luanda, Lusaka, Antananarivo,

Lilongwe, Windhoek, Porto-Novo, Harare, Gaborone, Maseru, Cape Town, Bloemfontein,

Algiers, Mbabane, Lobamba, Monrovia, Freetown, Banjul, Dakar, Maputo, Lomé, Dili,

Nouakchott, Ouagadougou, Accra, Malabo, Amman, Vientiane, Yerevan, Tbilisi, Rome,

Malé, Nicosia, Kuwait City, Doha, Lima, Manama, Bandar Seri Begawan, Paris,

Helsinki, Berlin, Dublin, Reykjavík, London, Washington D.C., Athens, Budapest,

Oslo, Warsaw, Bratislava, Stockholm, Ottawa, Suva, Bucharest, Havana, Panama City,

Brasília, Bogotá, Santiago, Buenos Aires, Caracas, Mumabi, Chennai, Bengaluru,

Kolkata, Hyderabad, Pune, Ahmedabad, Jaipur, Surat, Visakhapatnam, Indore, New Delhi

Lucknow, Nagpur, Kochi, Kanpur, Guwahati, Coimbatore, Noida, Ghaziabad, Patna