30.9K

Introduction:

In the realm of industrial infrastructure, the choice of reliable and durable components is paramount. Steel fittings and flanges have emerged as indispensable elements, providing unparalleled strength, versatility, and longevity in various applications. Whether it’s in the oil and gas, petrochemical, or construction sectors, these robust components play a crucial role in ensuring the integrity and efficiency of pipelines, vessels, and equipment. In this blog, we delve into the world of steel fittings and flanges, exploring their importance, types, applications, and the latest advancements that drive this ever-evolving industry.

Understanding Steel Fittings and Flanges:

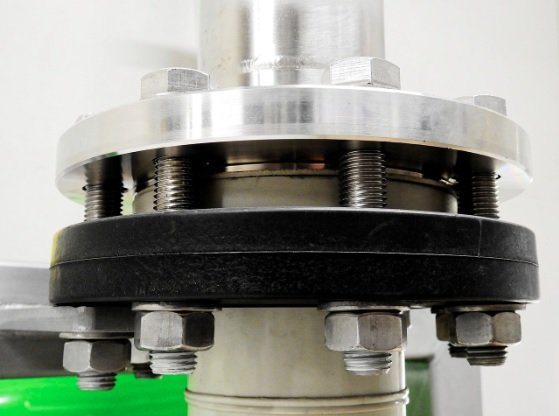

To comprehend the significance of steel fittings and flanges, it’s essential to grasp their basic definition and purpose. Steel fittings are connectors used to join or redirect the flow of fluids, gases, or solids within a piping system, while flanges act as interconnecting elements that allow for easy installation, maintenance, and dismantling of pipelines or vessels. This section provides an overview of the types of fittings and flanges commonly used in the industry, their materials, and the specific features that make them ideal for demanding environments.

Applications Across Industries:

Steel fittings and flanges find widespread application across multiple industries, ensuring the seamless operation of critical systems. From energy production and distribution to chemical processing, these components are relied upon to withstand high pressures, extreme temperatures, and corrosive environments. This section explores the diverse range of industries where steel fittings and flanges are employed, highlighting their role in facilitating efficient transportation, containment, and control of fluids and materials.

The Advantages of Steel Fittings and Flanges:

What makes steel fittings and flanges stand out among other materials? This section explores the advantages of utilizing steel components, such as their exceptional strength, resistance to corrosion, and ability to withstand harsh conditions. We delve into the inherent durability and longevity of steel fittings and flanges, examining how these qualities contribute to cost savings, reduced downtime, and increased safety for industrial operations.

Recent Technological Advancements:

Innovation continues to drive the steel fittings and flanges industry forward, enhancing performance, efficiency, and sustainability. This section sheds light on the latest advancements, such as improved manufacturing techniques, advanced materials, and enhanced design capabilities. We discuss the incorporation of digital technologies, including automation and predictive maintenance, and their impact on optimizing operations and ensuring the reliability of steel fittings and flanges.

Environmental Considerations:

In today’s world, environmental sustainability is a key concern. This section explores the steps taken by the steel fittings and flanges industry to mitigate its impact on the environment. From adopting eco-friendly manufacturing processes to implementing recycling and waste management initiatives, the sector is actively pursuing sustainable practices. We examine how steel fittings and flanges contribute to reducing energy consumption, minimizing emissions, and supporting the transition to a greener future.

Future Prospects and Emerging Trends:

As industrial infrastructure continues to evolve, so does the demand for advanced steel fittings and flanges. This section discusses the future prospects of the industry, considering factors such as expanding global infrastructure projects, technological breakthroughs, and evolving regulatory frameworks. We also explore emerging trends, such as the integration of smart sensors and IoT capabilities into steel components, enabling real-time monitoring and proactive maintenance.

Conclusion:

Steel fittings and flanges play a crucial role in the backbone of industrial infrastructure, enabling the efficient and reliable transportation of fluids and materials across a multitude of industries. With their unyielding strength, durability, and adaptability, these components ensure the integrity and longevity of critical systems. As the industry continues to evolve and embrace technological advancements, the future of steel fittings and flanges looks promising, promising even greater efficiency, sustainability,

Contact Adco forge today

Follow us on pinterest