ASME B16.11 Equal Tee Manufacturers and Suppliers:

A Forged Tee is a type of pipe fitting that is commonly used to branch off a pipeline or to connect pipes of different diameters. It is called a “forged” tee because it is made by heating and shaping a piece of metal, usually steel or stainless steel, into the desired tee shape.

The dimensions of a forged tee depend on the size and type of pipe it is meant to connect. Typically, forged tees are available in a range of sizes from 1/8″ to 4″ and in various thicknesses to meet different pressure requirements.

ISO Approved ASME/ANSI B16.11 Socket Weld Reducing Tee Manufacturer In India, ASME B16.11 Threaded Lateral Tee, MSS SP-79, 83, 95, 97, BS 3799 Forged Equal Tee, Dimensions Chart, Tolerances, Weight Chart, Thickness Chart, Cad Drawing Screwed Threaded Tee

ADCO Forge and Fittings is a reputable manufacturer of Forged Tees and other piping products. specialize in custom forging and machining of high-quality steel and stainless steel fittings for various industries, including oil and gas, petrochemical, and power generation. Our state-of-the-art manufacturing facilities and experienced engineers ensure that products meet the highest standards of quality and performance, A Trusted Supplier for many customers worldwide.

There are several types of forged tees available, including:

Equal Tee: An Equal Tee is a type of forged tee where all three branches of the tee are of the same size.

Reducing Tee: A Reducing Tee is a type of forged tee where one or two of the branches are of a smaller size than the main pipe.

Lateral Tee: A Lateral Tee is a type of forged tee that has a 45-degree or 90-degree bend in one of the branches, allowing for a change in the direction of the flow.

Threaded Tee: A Threaded Tee is a type of forged tee that has threaded connections on all three branches, allowing for easy installation and disassembly.

Socket Weld Tee: A Socket Weld Tee is a type of forged tee where the branches are connected to the main pipe using a socket weld connection.

Overall, forged tees are a versatile and essential component in various piping systems, and choosing the right type and size of tee is critical for ensuring safe and efficient operation.

We have the ready inventory of Socket Weld Equal Tee in the different size ranges of 1/2 Npt, 2 x 1 Npt, 3/4 Npt, 2 Inch, 1 Inch, 3 Inch, 4 Inch, 5 Inch, 6 Inch, 7 Inch, 8 Inch, 1 1/4 Emt, 2 x 1/2 Emt, 3 x 1 Npt, 4×4 npt, 6×4 Npt, 8 x 6 Npt Threaded Reducing Tees.

Socket Weld Tee Standard Specifications

Standards

ANSI / ASME B16.11, MSS SP-79, 83, 95, 97, BS 3799

Pressure Class

2000LBS, 3000LBS, 6000LBS, 9000LBS

Types

Socket Weld (Weld In)| Threaded / Screwed (NPT or BSPP)

Dimensions

ASME/ ANSI B16.11 | MSS-SP-79, 83, 95, 97 | BS3799 | BS4504 | BS10

Size Range (inches)

1/8″~4″ (DN6~DN100)

Forms

Equal/Reducing/Lateral Tee

Socket Weld Equal Tee in Stainless Steel 304/304L, SS 316/316L, 904L, Alloy 20, Carbon A234 WPB, Nickel 200, Monel, Inconel, Hastelloy C22, Duplex Steel 2205, Titanium, Copper Nickel, SMO 254, Aluminum, Brass, Cast Iron, Galvanized, MS Threaded Reducing Tee. Get best Price List.

ASME B16.11 Forged Fittings Types

If you are looking for ASME B16.11 Fittings types, weight chart, size chart, tolerance, and dimensions with drawings then kindly click the below-mentioned forms of pipe fittings as per your requirements to get the complete details. For the quick quote / price list click here.

ASME B16.11 Threaded Tee Material Grades

| Stainless Steel Forged Tee : | ASTM A182/SA182 F304, F304L, F316, F316L, F304H, F316H, F317, F317L, F321, F321H, F347, F347H, F446, F904L |

|---|---|

| Carbon Steel Forged Tee: | ASTM/ ASME A 105 F42, F46, F60, F65, F52, F56, and F70, ASTM/ ASME A 350 LF 2, A350 LF3 |

| Alloy Steel Forged Tee: | ASTM / ASME A 182 GR F5, F 9, F 11, F 12, F 22, F 91 |

| Duplex & Super Duplex Forged Tee: | ASTM A 182 –F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 S 31803, S 32205, S 32550, S 32750, S 32760 |

| Nickel Alloy Forged Tee: | ASTM / ASME SB 151, 152, 61, and 62 UNS NO. C 70600 (CU -NI- 90/10) , C 71500 (CU -NI- 70/30) / Nickel Alloy Forged Fittings ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276), UNS 8020 (ALLOY 20 / 20 CB 3), |

| Brass Forged Tee: | Brass CA 360, CA 345 and CA 377 / SAE J530, SAE J531 and ASA |

ASME B16.11 Forged Tee Dimensions

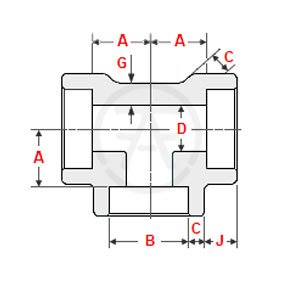

ASME B16.11 Equal Tee - Socket Weld - Dimensions

Dimensions of Socket Weld Equal Tee (NPS 1/2 to 4, Class 3000)

| NPS | Socket Bore | Depth Socket | Bore dia | Socket WT |

Body WT |

Center to bottom of socket |

|---|---|---|---|---|---|---|

| B | J | D | C | G | A | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

3.90 | 19.5 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

5.10 | 32 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

7.00 | 41.5 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

7.60 | 57.5 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

8.55 | 66.5 |

Dimensions of Socket Weld Reducing Tee (NPS 1/2 to 4, Class 6000)

| NPS | Socket Bore | Depth Socket | Bore dia | Socket WT |

Body WT |

Center to bottom of socket |

|---|---|---|---|---|---|---|

| B | J | D | C | G | A | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

5.95 5.20 |

4.80 | 19.5 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

6.95 6.05 |

5.55 | 22.5 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

7.90 6.95 |

6.35 | 27 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

7.90 6.95 |

6.35 | 32 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

8.90 7.80 |

7.15 | 38 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

10.90 9.50 |

8.75 | 41 |

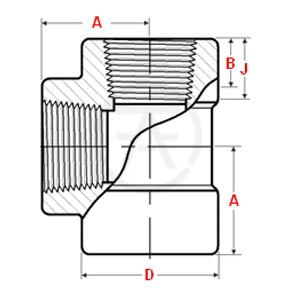

ASME B16.11 Tees - Threaded - Dimensions

Dimensions of Threaded Tees (NPS 1/2 to 4, Class 2000)

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

|---|---|---|---|---|---|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Dimensions of Threaded Equal Tee (NPS 1/2 to 4, Class 3000)

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

|---|---|---|---|---|---|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

Dimensions of Threaded Reducing Tee (NPS 1/2 to 4, Class 6000)

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

|---|---|---|---|---|---|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

ASME B16.11 Tee Fittings Tolerance

| "A" - Center to bottom of socket | FOR SIZES 1/8" AND 1/4" |

± 0.03" |

|---|---|---|

| 3/8", 1/2" AND 3/4" | ± 0.06" | |

| 1", 1-1/4", 1-1/2" AND 2" | ± 0.08" | |

| 2-1/2", 3", AND 4" | ± 0.10" | |

| "B" - Bore diameter of socket | FOR SIZES 1-1/2" AND SMALLER |

+ 0.020" - 0.000" |

| 2", 2-1/2", 3" AND 4" | + 0.025" - 0.000" |

|

| "C" - Socket wall thickness | MINIMUM = 1.09 T (BUT NOT LESS THAN 5/32") T = WALL THICKNESS OF NOMINAL PIPE |

|

| "D" - Bore diameter of fitting | FOR SIZES 2" AND SMALLER |

± 0.030" |

| 2-1/2", 3" AND 4" | ± 0.060" | |

| "E" - Bottom to bottom of sockets - couplings | FOR SIZES 1/8" AND 1/4" |

± 0.06" |

| 3/8", 1/2" AND 3/4" | ± 0.12" | |

| 1", 1-1/4", 1-1/2" AND 2" | ± 0.16" | |

| 2-1/2", 3", AND 4" | ± 0.20" | |

| "F" - Bottom of socket to opposite face - half couplings | FOR SIZES 1/8" AND 1/4" |

± 0.03" |

| 3/8", 1/2" AND 3/4" | ± 0.06" | |

| 1", 1-1/4", 1-1/2" AND 2" | ± 0.08" | |

| 2-1/2", 3", AND 4" | ± 0.10" | |

| "G" - Welding gap | APPROXIMATELY 0.06" RECOMMENDED GAP BEFORE WELDING |

|

| "H" - Minimum flat | MINIMUM FLAT = 0.75 X MINIMUM SOCKET WALL THICKNESS |

|

Q: What is a tee threaded?

A: A tee threaded refers to a type of tee fitting used in plumbing and piping systems. It features three openings, forming a “T” shape, where one end is threaded to allow for connection with threaded pipes or fittings.

Q: How is a forged tee made?

A: A forged tee is manufactured through a process called forging. It involves shaping a solid piece of metal, typically stainless steel or carbon steel, into a tee shape using heat and pressure. The metal is heated and then hammered or pressed into the desired tee configuration, resulting in a strong and durable fitting.

Q: What are the different types of tee fittings?

A: Tee fittings come in various types to suit different applications:

- Equal tee: This type has three openings of the same size, forming a 90-degree branch.

- Reducing tee: It has three openings with different sizes, allowing for connection of pipes or fittings of different diameters.

- Barred tee: This tee features a welded bar or plate across the branch opening, providing additional support and reinforcement.

- Lateral tee: It has one inlet and two outlets at a 45-degree angle, enabling flow diversion in different directions.

- Wye tee: Similar to a lateral tee, it has one inlet and two outlets, but the outlets are at a 90-degree angle, forming a “Y” shape.

Q: What is a welded tee?

A: A welded tee is a type of tee fitting that is formed by welding the branch pipe or fitting to the mainline pipe. This method ensures a strong and leak-proof connection. Welded tees are commonly used in applications where high pressure or high-temperature conditions are involved.

Q: How do you size a pipe tee?

A: Sizing a pipe tee involves considering the diameter of the mainline and branch pipes. The size of the tee is determined by the nominal pipe size (NPS) or the inside diameter (ID) of the pipe. It is crucial to match the tee size with the corresponding pipe sizes to ensure proper flow and functionality within the system. Consult piping codes, standards, or engineering references to determine the appropriate sizing for your specific application.

MSS SP-97 Socket Weld Lateral Tee Applications

Oil and Gas

Nuclear Power & Defence

Petrochemical

LNG

Desalination

Mining & Minerals

Myanmar, Nepal, Thailand, Vietnam, Philippines, Malaysia, Indonesia,

Singapore, Taiwan, Tasmania, Sri Lanka, Bangladesh, Bhutan, Cambodia,

Australia, New Zealand, Afghanistan, Tajikistan, Kyrgyzstan, Kazakhstan,

Uzbekistan, Turkmenistan, Iran, United Arab Emirates(UAE), Saudi Arabia,

Oman, Yemen, Iraq, Azerbaijan, Turkiye, Syria, Lebanon, Israel, Kenya,

Egypt, South Sudan, Eritrea, Djibouti, Ethiopia, Libya, Rwanda, Mali,

Niger, Chad, Central Africa Republic, Nigeria, Cameroon, Somalia, DRC,

Uganda, Tanzania, Angola, Zambia, Madagascar, Malawi, Namibia, Benin,

Zimbabwe, Botswana, Lesotho, South Africa, Algeria, Tunisia, Morocco,

Eswatini, Liberia, Sierra Leone, The Gambia, Senegal, Mozambique, Togo,

Mauritania, Burkina Faso, Ghana, Equatorial Guinea, Jordan, Timor-Leste,

Palestine, Laos, Armenia, Georgia, Maldives, Cyprus, Kuwait, Qatar, Peru,

Bahrain, Brunei, Finland, France, Germany, Ireland, Iceland, UK, US,

Greece, Hungary, Italy, Norway, Poland, Slovakia, Sweden, Canada, Fiji,

Romania, Cuba, Panama, Brazil, Colombia, Chile, Argentina, Venezuela,

Naypyidaw, Kathmandu, Bangkok, Hanoi, Manila, Kuala Lumpur, Jakarta, Tunis,

Jurong East, Taipei City, Hobart, Sri Jayawardenepura Kotte, Dhaka, Thimphu,

Phnom Penh, Canberra, Wellington, Kabul, Dushanbe, Bishkek, Astana, Abuja,

Tashkent, Ashgabat, Tehran, Abu Dhabi, Riyadh, Muscat, Sana’a, Baghdad, Pretoria,

Baku, Ankara, Damascus, Beirut, Jerusalem, Nairobi, Cairo, Juba, Asmara, Rabat,

Djibouti city, Addis Ababa, Tripoli, Kigali, Bamako, Niamey, N’Djamena, Bangui,

Yaoundé, Mogadishu, Kinshasa, Kampala, Dodoma, Luanda, Lusaka, Antananarivo,

Lilongwe, Windhoek, Porto-Novo, Harare, Gaborone, Maseru, Cape Town, Bloemfontein,

Algiers, Mbabane, Lobamba, Monrovia, Freetown, Banjul, Dakar, Maputo, Lomé, Dili,

Nouakchott, Ouagadougou, Accra, Malabo, Amman, Vientiane, Yerevan, Tbilisi, Rome,

Malé, Nicosia, Kuwait City, Doha, Lima, Manama, Bandar Seri Begawan, Paris,

Helsinki, Berlin, Dublin, Reykjavík, London, Washington D.C., Athens, Budapest,

Oslo, Warsaw, Bratislava, Stockholm, Ottawa, Suva, Bucharest, Havana, Panama City,

Brasília, Bogotá, Santiago, Buenos Aires, Caracas, Mumabi, Chennai, Bengaluru,

Kolkata, Hyderabad, Pune, Ahmedabad, Jaipur, Surat, Visakhapatnam, Indore, New Delhi

Lucknow, Nagpur, Kochi, Kanpur, Guwahati, Coimbatore, Noida, Ghaziabad, Patna