ASME B16.9 End Cap Manufacturers and Suppliers:

ADCO Forge and Fittings is a renowned manufacturer of Buttweld End Cap, which is used to cap off the end of a pipe or tube. The company has an extensive range of buttweld end caps that are suitable for different applications.

The company offers end caps made from high-quality materials such as stainless steel, copper, and ductile iron, which are suitable for different applications. The weight chart for the end caps varies depending on the size and material used.

ISO Approved ASME/ANSI B16.9 End Pipe Cap Manufacturer In India, ASME B16.28 End Cap Fitting, MSS SP-43 End Pipe Cap Dimensions Chart, Tolerances, Weight Chart, Thickness Chart, Cad Drawing

ADCO Forge and Fittings offers pipe caps made from various materials such as stainless steel, copper, and ductile iron. The company uses high-quality materials to ensure that the end caps pipe fittings are durable and long-lasting. The stainless steel end caps are resistant to corrosion and can withstand high temperatures, making them ideal for use in harsh environments. Copper end caps are suitable for use in plumbing systems, and ductile iron end caps are used in industrial applications.

The buttweld ANSI B16.9 end caps manufactured by ADCO come in various dimensions to fit different pipe sizes. The dimensions of the pipe cap fittings range from ½ inch to 48 inches in diameter. The thickness of the end caps also varies depending on the diameter of the pipe.

The weight chart for the buttweld MSS SP-43 end caps varies depending on the material used and the size of the end cap. The weight of the end caps ranges from a few pounds to several hundred pounds. End caps in piping systems is to cap off the end of a pipe or tube. This is done for several reasons, including:

- Protection: End caps are used to protect the open end of a pipe or tube from external factors such as dirt, debris, and moisture. This helps to prevent damage to the interior of the pipe or tube, which could affect its functionality.

- Containment: End caps are used to contain the contents of a pipe or tube. This is important in applications where the contents need to be kept separate from the surrounding environment, such as in chemical or food processing plants.

- Aesthetics: End caps are used to improve the appearance of a piping system by covering the exposed end of a pipe or tube. This can give the system a more polished and professional look.

- Safety: End caps are used to prevent accidents and injuries that could result from exposed pipe ends. By capping off the end of a pipe or tube, the risk of injury from sharp edges or protruding objects is reduced.

We have the ready inventory of Buttweld End Caps in the different size ranges of 4 Emt, 6 Emt, 7 7/8 Npt, 7 1/2 Npt, 7 1/4 Emt, 7 5/8 Emt, 8 inch, 4 Corrugated Drain End Pipe Cap, 4 inch drain Pipe End Cap, 68mm drain Pipe End Cap, 160mm Drainage Pipe End Cap, 15mm gas Pipe End Cap.

Buttweld End Pipe Cap Standard Specifications

Standards

ANSI / ASME B16.9, MSS SP-43, API 590-605

Thickness

SCH10, SCH 20, SCH30, STD SCH40, SCH80, SCH60, XS, SCH100, SCH 120, SCH140, SCH 160, XXS available with NACE MR 01-75

Types

Welded | Seamless | Fabricated

Dimensions

ASME/ ANSI B16.9 | ASME B16.28 | MSS-SP-43 | BS1560 | BS4504 | BS10

Size Range (inches)

Seamless Cap ( 1/2″~24″)

ERW/Fabricated/Welded Cap (1/2″~48″)

Forms

Square, Round, Rectangular, “U” Shape, “I” Shape, Oval End Cap

Schedule 40 & Schedule 80 End Cap in Stainless Steel 304/304L, SS 316/316L, SS 904L, Alloy 20, Carbon A234 WPB, Nickel 200, Monel, Inconel, Hastelloy C22, Duplex Steel 2205, Titanium, Copper Nickel, SMO 254, Aluminum, Brass, Cast Iron, Galvanized, MS End Pipe Cap. Get best Price List.

ASME B16.9 Buttweld Fittings Types

ASME B16.9 End Pipe Cap Material Grades

| Stainless Steel End Cap: | ASTM A403/SA403 WP Gr. 304, 304L, 304H, 310, 310S, 316, 316L, 316H, 316Ti, 317, 317L, 321, 321H, 347, 347H, 446, 904L |

|---|---|

| Carbon Steel End Cap: | ASTM A860/SA860, ASTM A234/SA234, WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel End Cap: | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel End Cap: | ASTM A234/SA234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Duplex & Super Duplex End Cap: | ASTM A815, ASME SA815 UNS S31803, S32205, S32750, S32760. Werkstoff No. 1.4462, 1.4410 |

| Nickel Alloy End Cap: | ASTM / ASME SB B366 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UND 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C276 ), Cupro Nickel 90/10 ( C70600, 2.0872 ), 70/30 ( C71500, 2.0882) |

| Other Steel End Cap: | ASTM B363 Titanium Grade 2 ( R50400, 3.7035 ), Titanium Grade 2 ( N56400, 3.7165 ), ASTM A403 SMO 254/AL-6XN ( S31254, 1.4547 ), AISI 4130 ( G41300, 1.7218 ) |

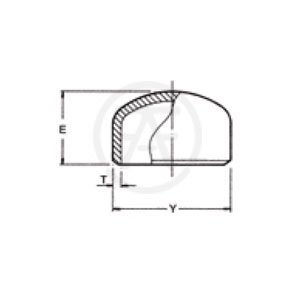

ASME B16.9 End Cap Dimensions and Weights Chart

ASME B16.9 Buttweld End Pipe Cap - Dimensions and Weights Chart

Dimensions and weights of Buttweld End Cap (NPS 1/2 to 24, schedule STD/XS)

| Buttweld Cap Nominal Size |

Pipe Cap Outside Diameter Y |

Pipe Cap Wall Thickness T |

Buttweld Cap End to End |

Buttweld Cap Weight |

||

|---|---|---|---|---|---|---|

| mm | in | mm | mm | Schedule | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | ||

| 3.73 | X.S | |||||

| 20 | 3/4” | 26.7 | 2.87 | STD | ||

| 3.91 | X.S | |||||

| 25 | 1” | 33.4 | 3.38 | STD | 38.1 | 0.1 |

| 4.55 | X.S | 38.1 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 38.1 | 0.14 |

| 4.85 | X.S | 38.1 | 0.18 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 38.1 | 0.18 |

| 5.08 | X.S | 38.1 | 0.23 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 38.1 | 0.27 |

| 5.54 | X.S | 38.1 | 0.32 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 38.1 | 0.41 |

| 7.01 | X.S | 38.1 | 0.45 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 0.64 |

| 7.62 | X.S | 50.8 | 0.82 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 1.13 |

| 8.56 | X.S | 63.5 | 1.54 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 76.2 | 1.91 |

| 9.5 | X.S | 76.2 | 2.59 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 88.9 | 2.95 |

| 10.97 | X.S | 88.9 | 4.1 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 101.6 | 5.0 |

| 12.7 | X.S | 101.6 | 7.3 | |||

| 250 | 10” | 273.0 | 9.27 | STD | 127.0 | 9.1 |

| 12.7 | X.S | 127.0 | 12.0 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 152.4 | 13.6 |

| 12.7 | X.S | 152.4 | 17.0 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 165.1 | 15.9 |

| 12.7 | X.S | 165.1 | 21.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 178.8 | 20.0 |

| 12.7 | X.S | 178.8 | 26.0 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 203.2 | 26.0 |

| 12.7 | X.S | 203.2 | 34.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 228.6 | 33.0 |

| 12.7 | X.S | 228.6 | 43.0 | |||

| 600 | 24” | 610.0 | 9.52 | STD | 266.7 | 46.0 |

| 12.7 | X.S | 266.7 | 61.0 | |||

Buttweld Fittings ASME B16.9 End Cap Tolerance

| Buttweld Fittings ASME B16.9 End Cap Tolerance | Pipe Cap | |||

|---|---|---|---|---|

| Buttweld Fitting Dimension (NPS) | Outside Diameter at Bevel |

Inside Diameter at End |

Wall Thickness T | Over-all Length F |

| 1/2 to 2-1/2 | +0.06 | Not less than 87.5% of nominal thickness |

+/- 0.12 | |

| -0.03 | ||||

| 3 to 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 5 to 8 | +/- 0.06 | +/- 0.06 | +/- 0.25 | |

| 10 to 18 | +0.16 | +/- 0.12 | +/- 0.25 | |

| -0.12 | ||||

| 20 to 24 | +0.25 | +/- 0.19 | +/- 0.25 | |

| -0.19 | ||||

| 26 to 30 | +0.25 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||

| 32 to 48 | +0.25 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||

ASME/ANSI B16.9 Alignment Tolerances

ASME/ANSI B16.9 Alignment Tolerances (The way that the ends of a fitting are cut)

Exaggerated distortions are shown for clarity in the diagram above

| Nominal Pipe Size (NPS) | Off Plane Tolerances, ± A |

Off Angle Tolerances, ± B |

Alignment of Ends, ± C |

|||

|---|---|---|---|---|---|---|

| in | mm | in | mm | in | mm | |

| ½ to 4 | 0.06 | 2 | 0.03 | 1 | 0.03 | 1 |

| 5 to 8 | 0.12 | 4 | 0.06 | 2 | 0.03 | 1 |

| 10 to 12 | 0.19 | 5 | 0.09 | 2 | 0.06 | 2 |

| 14 to 16 | 0.25 | 6 | 0.09 | 3 | 0.06 | 2 |

| 18 to 24 | 0.38 | 10 | 0.12 | 4 | 0.06 | 2 |

| 26 to 30 | 0.38 | 10 | 0.19 | 5 | – | – |

| 32 to 42 | 0.50 | 13 | 0.19 | 5 | – | – |

| 44 to 48 | 0.75 | 19 | 0.19 | 5 | – | – |

MSS SP-43 End Pipe Cap Applications

Oil and Gas

Nuclear Power & Defence

Petrochemical

LNG

Desalination

Mining & Minerals

Myanmar, Nepal, Thailand, Vietnam, Philippines, Malaysia, Indonesia,

Singapore, Taiwan, Tasmania, Sri Lanka, Bangladesh, Bhutan, Cambodia,

Australia, New Zealand, Afghanistan, Tajikistan, Kyrgyzstan, Kazakhstan,

Uzbekistan, Turkmenistan, Iran, United Arab Emirates(UAE), Saudi Arabia,

Oman, Yemen, Iraq, Azerbaijan, Turkiye, Syria, Lebanon, Israel, Kenya,

Egypt, South Sudan, Eritrea, Djibouti, Ethiopia, Libya, Rwanda, Mali,

Niger, Chad, Central Africa Republic, Nigeria, Cameroon, Somalia, DRC,

Uganda, Tanzania, Angola, Zambia, Madagascar, Malawi, Namibia, Benin,

Zimbabwe, Botswana, Lesotho, South Africa, Algeria, Tunisia, Morocco,

Eswatini, Liberia, Sierra Leone, The Gambia, Senegal, Mozambique, Togo,

Mauritania, Burkina Faso, Ghana, Equatorial Guinea, Jordan, Timor-Leste,

Palestine, Laos, Armenia, Georgia, Maldives, Cyprus, Kuwait, Qatar, Peru,

Bahrain, Brunei, Finland, France, Germany, Ireland, Iceland, UK, US,

Greece, Hungary, Italy, Norway, Poland, Slovakia, Sweden, Canada, Fiji,

Romania, Cuba, Panama, Brazil, Colombia, Chile, Argentina, Venezuela,

Naypyidaw, Kathmandu, Bangkok, Hanoi, Manila, Kuala Lumpur, Jakarta, Tunis,

Jurong East, Taipei City, Hobart, Sri Jayawardenepura Kotte, Dhaka, Thimphu,

Phnom Penh, Canberra, Wellington, Kabul, Dushanbe, Bishkek, Astana, Abuja,

Tashkent, Ashgabat, Tehran, Abu Dhabi, Riyadh, Muscat, Sana’a, Baghdad, Pretoria,

Baku, Ankara, Damascus, Beirut, Jerusalem, Nairobi, Cairo, Juba, Asmara, Rabat,

Djibouti city, Addis Ababa, Tripoli, Kigali, Bamako, Niamey, N’Djamena, Bangui,

Yaoundé, Mogadishu, Kinshasa, Kampala, Dodoma, Luanda, Lusaka, Antananarivo,

Lilongwe, Windhoek, Porto-Novo, Harare, Gaborone, Maseru, Cape Town, Bloemfontein,

Algiers, Mbabane, Lobamba, Monrovia, Freetown, Banjul, Dakar, Maputo, Lomé, Dili,

Nouakchott, Ouagadougou, Accra, Malabo, Amman, Vientiane, Yerevan, Tbilisi, Rome,

Malé, Nicosia, Kuwait City, Doha, Lima, Manama, Bandar Seri Begawan, Paris,

Helsinki, Berlin, Dublin, Reykjavík, London, Washington D.C., Athens, Budapest,

Oslo, Warsaw, Bratislava, Stockholm, Ottawa, Suva, Bucharest, Havana, Panama City,

Brasília, Bogotá, Santiago, Buenos Aires, Caracas, Mumabi, Chennai, Bengaluru,

Kolkata, Hyderabad, Pune, Ahmedabad, Jaipur, Surat, Visakhapatnam, Indore, New Delhi

Lucknow, Nagpur, Kochi, Kanpur, Guwahati, Coimbatore, Noida, Ghaziabad, Patna